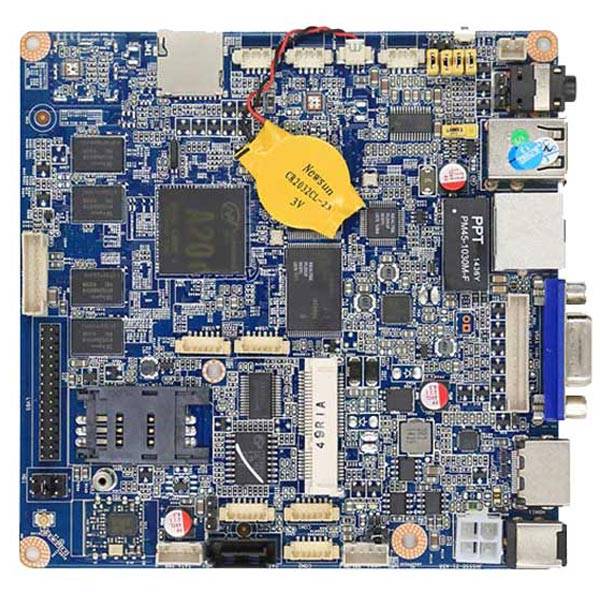

Main Pcb Assembly

Basic Information:

| Metal Coating: HASL ROHS | Mode of Production: SMT+ | Layers: 6 Layer PCB |

| Base Material: High Tg FR-4 | Certification: SGS, ISO, RoHS | MOQ: No MOQ |

| Solder Types: Lead-Free= | One-Stop Services: PCB Manufacturing And Turnkey PCB Assembly | Testing: 100% AOI / X-ray / E-testing |

| Tehnology Support: Free DFM (Design For Manufacturing) Check | Types Of Assemblies: SMT, THD, DIP, Mixed Technology PCBA | Standard: IPC-a-610d |

PCB and PCBA Quick Turn PCB Assembly

Keywords: PCB Assembly Service, PCB Assembly Process, prototype PCB, PCB Assembly Manufacturers, PCB Assembly

PCBFuture is the fabrication company which believes in delivering excellence with is expertise and experiences. Our expertise lies in high density single layer and double sided and multilayer PCBs. We have extensive experience in PCB manufacturers, with automatic production lines and automatic inspection facilities.

Why choose?

We have professional team 24/7 customer support.

We have full-time experienced technical support.

We provide products delivered on time.

We render quick turn PCB services and after-sales services.

We are capable of larger production

We have in-house full services capabilities.

The perfect combination of factory price and customized service.

We can provide below services:

PCB Manufacturing

Components sourcing

Through hole PCB assembly

SMT PCB assembly

Quick turn PCB assembly

Turnkey PCB assembly

Low volume PCB assembly

Mid volume PCB assembly

We offer Quick turn PCB due date as follows:

2 layer quick turn PCB — 1day

4-6 layer quick turn PCB –3 days

8-10 layer quick turn PCB –5 days

12-16 layer quick turn PCB –6 days

16-20 layer quick turn PCB — 6 days

Finishes we are able to provide our customers

HASL – Leaded Solder Tin/Nickel

HASL – Lead Free Solder

Chemical soft gold

Wire Bondable Soft Gold

Nickel Flash Gold

Electroless Nickel

Immersion Gold OSP

Electrolytic Nickel /Hard Gold and Selective Gold

Immersion Silver

Immersion Tin

Carbon Ink

ENIG

Our mission is to offer industry with reliable advanced PCB manufacturing and assembly services from prototype to production in a cost-effective manner. Our aim is to help each user become a well-rounded, multidisciplinary practitioner who can confidently bring innovative, cutting-edge engineering ideas to bear on any number of relevant tasks, problems and technologies. We hope our advantages will enable you to get more profits.

If you have any questions or enquires, feel free to contact sales@pcbfuture.com , we will reply to you ASAP.