What’s the standard to choose the components and materials when assembly PCB?

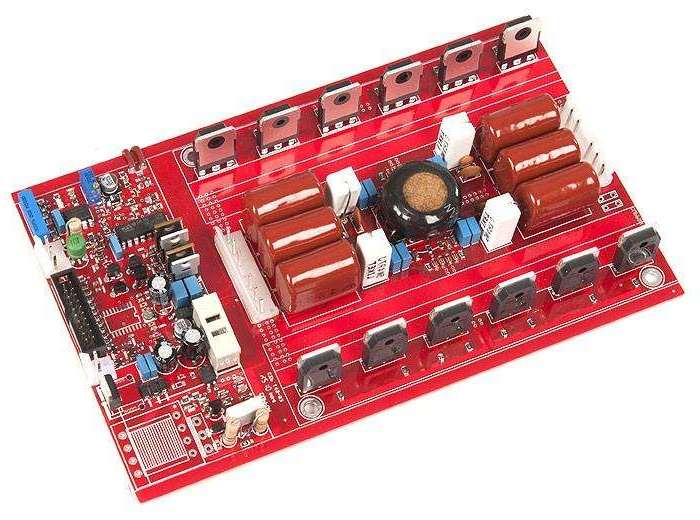

PCB assembly processing includes printed circuit design, PCB prototyping, SMT PCB board, component sourcing and other processes. So, what are the PCBA board processing components and substrate selection standards?

1. Selection of components

The selection of components should take full account of the actual area of SMB, and the conventional components should be selected as far as possible. The small-size components should not be blindly pursued to avoid increasing the cost. IC devices should note that the pin shape and pin spacing; QFP with less than 0.5mm pin spacing should be considered carefully, you can directly using BGA package.

In addition, the packaging form of components, solderability of PCB, reliability of SMT PCB assembly, and temperature bearing capacity should be taken into account. After selecting components, the database of components must be established, including installation size, pin size and SMT manufacturer and other relevant data.

2.Selection of base material for PCB

The base material shall be selected according to the service conditions of SMB and the requirements of mechanical and electrical performance. The number of copper clad foil surfaces (single, double or multi-layer) of the substrate is determined according to the SMB structure; the thickness of the substrate is determined according to the size of SMB and the quality of components per unit area. When you selecting SMB substrates, factors such as electrical performance requirements, Tg value (glass transition temperature), CTE, flatness and price etc… should be considered.

The above is the brief summary of printed circuit board assembly processing components and substrate selection standards. For more details, you can visit directly to our website: www.pcbfuture.com to learn more!

Post time: Apr-29-2021