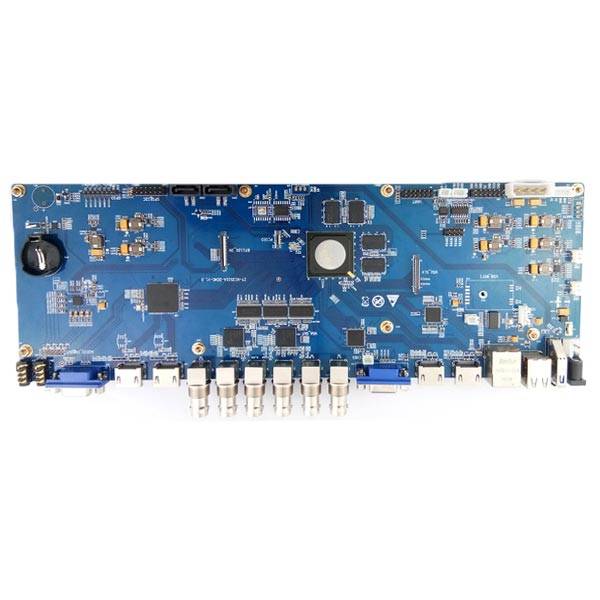

Main Board PCB Assembly China

Basic Information:

| Metal Coating: HASL lead free | Mode of Production: SMT+ | Layers: 6 Layer PCB |

| Base Material: High Tg FR-4 | Certification: SGS, ISO, RoHS | MOQ: No MOQ |

| Solder Types: Lead-Free (RoHS Compliant) | One-Stop Services: PCB Manufacturing And Turnkey PCB Assembly | Testing: 100% AOI / X-ray / Visual Test |

| Tehnology Support: Free DFM (Design For Manufacturing) Check | Types Of Assemblies: SMT, THD, DIP, Mixed Technology PCBA | Standard: IPC-a-610d |

PCB and PCBA Quick Turn PCB Assembly

Keywords: PCB Assembly Service, PCB Assembly Process, PCB Population, PCB Assembly Manufacturers, PCB Assembly Cost, Cheap PCB Assembly, Printed Circuit Board Assembly Companies

What is PCB and PCBA means?

PCB refer to Printed Circuit Board, it is a board that electrically connects electronic components. PCB are use

Copper pads, conductive tracks, and other features etched from copper foil laminated onto a non-conductive substrate.

PCBA refer to Printed Circuit Board Assembly, once the PCB are soldered by parts and all electronic components, the populated board process is called PCB Assembly. Then the board could realize the electronic function for electronic product.

PCBFuture is committed to supply high quality and economically PCB manufacturing and One stop PCB assembly service to all world customers. From quick-turn prototyping, low volume high mix to high volume production, we always keep in mind that top quality, on time delivery, competitive price and impeccable service are the only way to win your loyalty. This allows you, the honored customer, to focus on your core business well assured that your needs are in safe and expert hands.

Quality Assurance

Incoming Quality Control

We establish international standards and customer standards for incoming inspection specifications and requirements. Only qualified brand raw materials will be used. We have continuously track and promote suppliers quality improvement actives.

In-Process Quality Control

PCBFuture always consider high-quality electronic products are manufactured, not inspected. We have a standardized related documents and detailed manufacturing instructions for each process of the production line to ensure the correct implementation of the manufacturing specifications and standards.

Final Quality Control

We strictly follow the customer requirements and international quality standards to inspect and control the electronic PCB quality. Also we will timely follow up the quality performance of the products and our service after delivery, and take quick and effective improvement actions for the feedback of customers.

We can provide below services:

PCB Manufacturing

Components sourcing

Through hole PCB assembly

SMT PCB assembly

Testing and programming

Prototype PCB assembly

Low cost PCB assembly

Quick turn PCB assembly

Turnkey PCB assembly

Low volume PCB assembly

Mid volume PCB assembly

Electronic assembly process:

1. PCB Manufacturing & Components Sourcing

2. Screen Printing of Solder Paste onto PCB Board

3. Lead-free PCB Assembly

4. Burning Program and In-Circuit Test (ICT)

Files we need to check the PCB assembly cost

• Gerber files

• BOM List

• Quantity and Lead time

• Other production and test information

Normally, we can quote turnkey electronic assembly orders in 2 days. If customer need urgently, we can quote in 2 hours.

Many customers often face the problem of sourcing components for their PCB assembly projects. It will be exhausted for their energy and resources, because sourcing from multiple component suppliers and their PCB assembly house for lead times, component shortages and overages, part substitutes, and logistics. PCBFuture are striving to offer best PCB assembly service to you, so you can focus on design and customer service.

If you have any questions or enquires, feel free to contact sales@pcbfuture.com , we will reply to you ASAP.