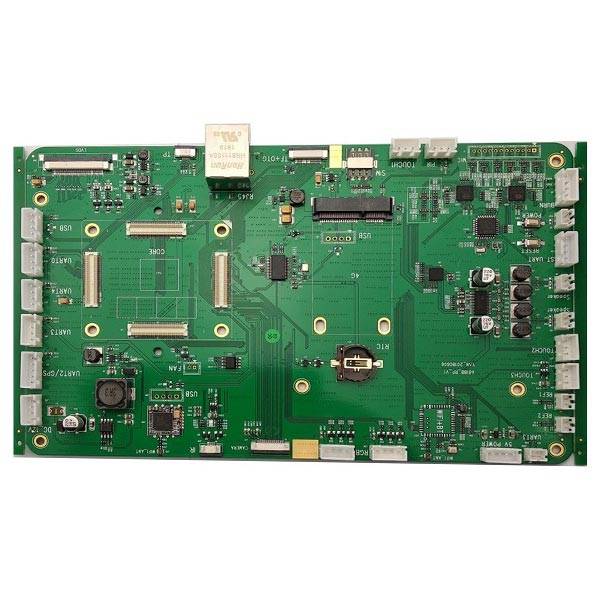

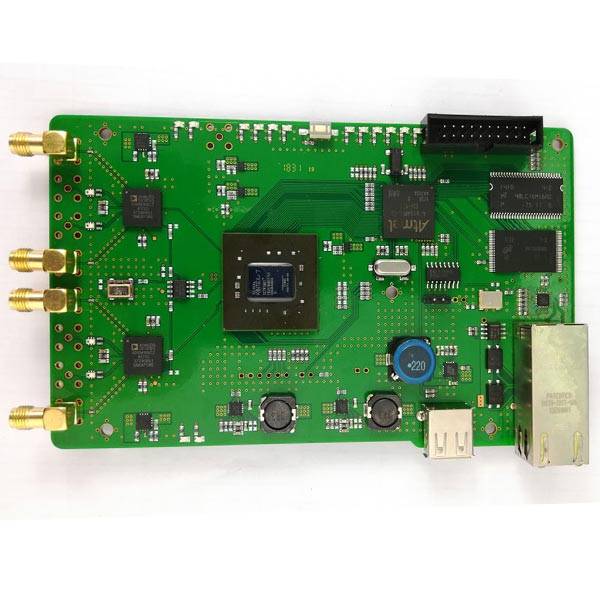

Low Cost Pcb Assembly Factory Companies – Printed Wiring Assembly – KAISHENG

Low Cost Pcb Assembly Factory Companies – Printed Wiring Assembly – KAISHENG Detail:

Basic Information:

| Metal Coating: HASL (RoHS) | Mode of Production: SMT+ | Layers: 2 Layer PCB |

| Base Material: High Tg FR-4 | Certification: SGS, ISO | MOQ: No MOQ |

| Solder Types: Lead-Free | One-Stop Services: Turnkey PCB Assembly | Testing: E-test / Visual Test |

| Tehnology Support: Free DFM (Design For Manufacturing) Check | Types Of Assemblies: SMT, THD, DIP, Mixed Technology PCBA | Standard: IPC-a-610d |

PCB and PCBA Quick Turn PCB Assembly

Keywords: PCB Assembly Process, PCB Population, PCB Assembly Manufacturers, PCB Assembly Cost, Cheap PCB Assembly

PCBFuture is a highly certified, premier electronics contract fabrication company providing PCB Assembly, PCB fabrication, and PCB turnkey services. Our equipment, systems and processes are optimized for flexibility in building complex products that have medium volume/high mix requirements. PCBFuture is good at providing quality Printed Circuit Design and Turnkey prototype and production solutions to the electronic community.

Why choose?

1. Excellent customer service.

2. Affordable and competitive prices.

3. Competitive price and no minimum cost

4. Function test based on customer’s specific requirements

5. No additional tooling charge for reorders.

We can provide below services:

One-stop PCB fabrication and assembly

Cheap PCB assembly

Prototype PCB assembly services (quantities from 1 to 25 boards)

Quick turn PCB assembly

Single or double sided SMT assembling

Thru-hole Assembly, EMS PCB, and mixed prototype assembly

PCBA Function test

Personalized and standardized service

The value-added services of industrial control board PCBA foundry material of PCBFuture:

There is no minimum order requirement for MOQ, samples and small and medium batch orders are welcome.

Optimize the manufacturing process. We can provide solutions such as low efficiency, high defect rate, and potential quality hazards in the production process.

Optimize the design plan to solve product design problems and reduce product design costs. PCB Layout file modification or drawing board.

How do you ensure the final quality of the product?

For PCB, we will use flying probe test, electronic test, etc.

For PCBA, we need you to provide a method or test fixture for functional testing. Before that, our inspectors will use a microscope and X-ray to check the IC foot welding or bad solder, etc.

Our team works closely with customer, the board manufacturers, and our in-house assembly personnel with the common goal of producing quality circuit boards that meet our customer’s specifications, and exceeds our customer’s expectations. Our customer’s recognition as “Best Valued Supplier” is achieved with accurate and concise data, quality manufacturing, and on-time delivery. If you have any questions or enquires, feerly contact sales@pcbfuture.com , we will reply to you ASAP.

Product detail pictures:

Related Product Guide:

We normally believe that one's character decides products' quality, the details decides products' high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Low Cost Pcb Assembly Factory Companies – Printed Wiring Assembly – KAISHENG, The product will supply to all over the world, such as: Spain, Swaziland, Washington, We aspire to meet the demands of our customers globally. Our range of products and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.