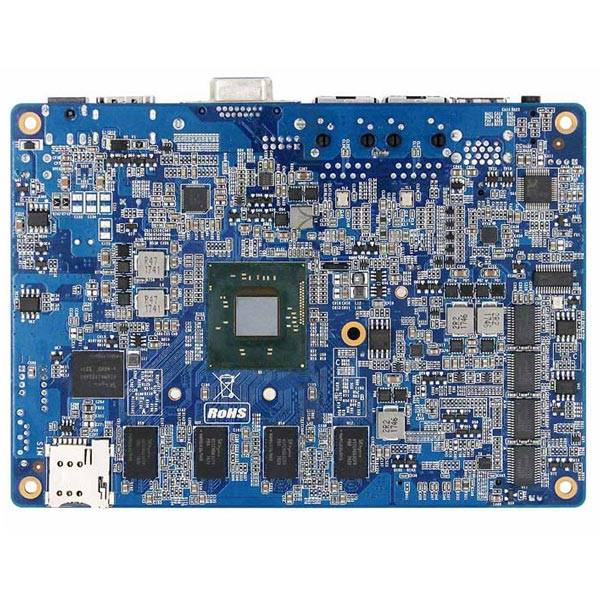

Low Cost Flexible Pcb Assembly Manufacturers – Main Pcb Assembly – KAISHENG

Low Cost Flexible Pcb Assembly Manufacturers – Main Pcb Assembly – KAISHENG Detail:

Basic Information:

| Metal Coating: HASL lead free | Mode of Production: SMT+ | Layers: 4 Layer PCB |

| Base Material: High Tg FR-4 | Certification: SGS, ISO, RoHS | MOQ: No MOQ |

| Solder Types: RoHS Compliant | One-Stop Services: Turnkey PCB | Testing: E-test / Visual Test |

| Tehnology Support: Free DFM (Design For Manufacturing) Check | Types Of Assemblies: SMT, THD, DIP, Mixed Technology PCBA | Standard: IPC-a-610d |

PCB and PCBA Quick Turn PCB Assembly

Keywords: PCB Assembly Service, PCB Assembly Proces, PCB Assembly Cost, Cheap PCB Assembly, Quick Turn PCB

Quick Turn PCB in China

PCBFuture is focus on offer customers with high quality quick turn PCB fabrication services and fast and timely delivery services. If you have requirements for rapid PCB manufacturing, we are your good choice. You can get what you need in terms of speed, efficiency, quality and price in here.

In the process of manufacturing quick turn PCB, we will use the most suitable and economical materials to save costs according to your requirements.

Due to the particularity of quick turn PCB to delivery cycle, if there is a problem with the product quality, it will not only delay the time, but also cause unnecessary production waste and increase costs..

If you demand quick turn PCB Board, just tell us your idea, we will make it!

PCBFuture is a PCBA OEM manufacturer that provides the professional PCB fabrication, material procurement, turnkey PCB rapid production and other high-quality services with customers.

Why choose?

1. Low purchasing cost

2. Low labor cost

3. Introduced a large number of advanced equipment to improve production efficiency

4. Fast and delivery on time

5. Clear responsibilities

We can provide below services:

PCB Manufacturing

Components sourcing

Through hole PCB assembly

Mid volume PCB assembly

Actual PCBA process steps.

Step 1: Solder Paste Stenciling

Step 2: Pick and Place

Step 3: Reflow Soldering

Step 4: Inspection and Quality Control

Step 5: Through-Hole Component Insertion

Step 6: Final Inspection and Functional Testing

PCBFuture focus on high quality and cost effective printed circuit boards, and its unparalleled consistency and customer-centricity has earned it respect and appreciation on a global level. Our goal is to help each user become a well-rounded, multidisciplinary practitioner who can confidently bring innovative, cutting-edge engineering ideas to bear on any number of relevant tasks, problems, and technologies.

If you have any questions or enquires, feel free to contact sales@pcbfuture.com , we will reply to you ASAP.

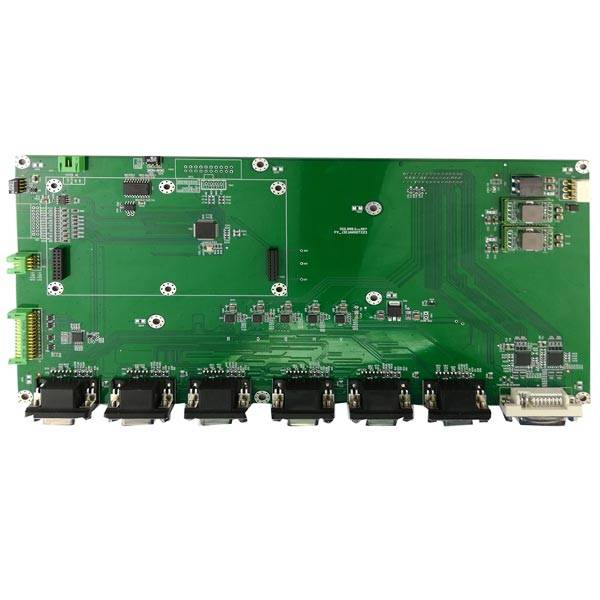

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for Low Cost Flexible Pcb Assembly Manufacturers – Main Pcb Assembly – KAISHENG, The product will supply to all over the world, such as: Pakistan, venezuela, Tunisia, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.