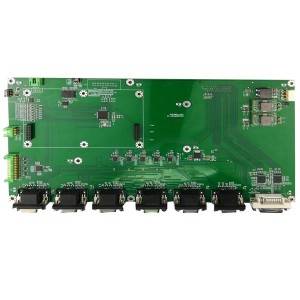

Full Turnkey Assembly

Basic Information:

| Metal Coating: HASL LEAD FREE | Mode of Production: SMT+ | Layers: 2 Layer PCB |

| Base Material: FR-4 tg135 | Certification: SGS, ISO, RoHS | MOQ: No MOQ |

| Solder Types: Lead-Free (RoHS Compliant) | One-Stop Services: Low volume PCB assembly | Testing: 100% AOI / E-test / Visual Test |

| Tehnology Support: Free DFM (Design For Manufacturing) Check | Types Of Assemblies: SMT, THD, DIP, Mixed Technology PCBA | Standard: IPC-a-610d |

PCB and PCBA Quick Turn PCB Assembly

Keywords: PCB Assembly Service, PCB Assembly Process, PCB Population, PCB Assembly Manufacturers, Turn-Key

PCBFuture provides the best in PCB fabrication and Assembly services. We have a complete ESD protection and ESD testing services helmed by a dedicated staff of professionals. Over the past ten years, PCBFuture has continued to grow and develop because we have always been committed to providing the best customer service and product quality.

Why choose our PCB assembly services?

1. In partial Turn-Key, you can order the PCBs and partial components. Our Engineers have decades of PCB fabrication experience to ensure the placement of parts meets circuit and mechanical architecture needs.

2. PCBFuture can providing high quality bare PCBs and printed circuit board assemblies at very competitive prices with outstanding service and timely delivery.

3. With our resources and experience, we have what it takes to meet your project needs from concept to production and also be your complete electronic engineering partner no matter how large or small your project is.

We can provide below services:

PCB Manufacturing

Testing and programming

Prototype PCB assembly

Turn-Key Circuit Board Assembly Services

Quality inspection and final assembly

How to ensure electronic components are original

1. You must not purchase second-hand materials and fake materials cheaply. You should purchase from the original factory designated agents and other formal channels, such as Dejie, Mouser, Arrow, etc.;

2. The purchased materials must be compared with the production BOM to ensure that the brand and model are correct;

3. Unless the customer has specified requirements, the purchased materials are best produced by formal manufacturers, and the quality is guaranteed;

4. The purchased materials must be checked to confirm the materials function properly;

5. The purchased materials should be stored reasonably to avoid quality problems such as dampness due to improper storage of materials.

How to choose the PCB assembly manufacturer?

1. The degree of factory specialization.

2. Service awareness.

3. Industry experience.

4. The price of PCBA processing is relatively transparent.

We are helpful, attentive and supportive with a proactive approach to help you win in competitive markets. As for our prices, you will find them the most affordable. If you have any questions or enquires, please feel free to contact sales@pcbfuture.com , we will reply to you ASAP.