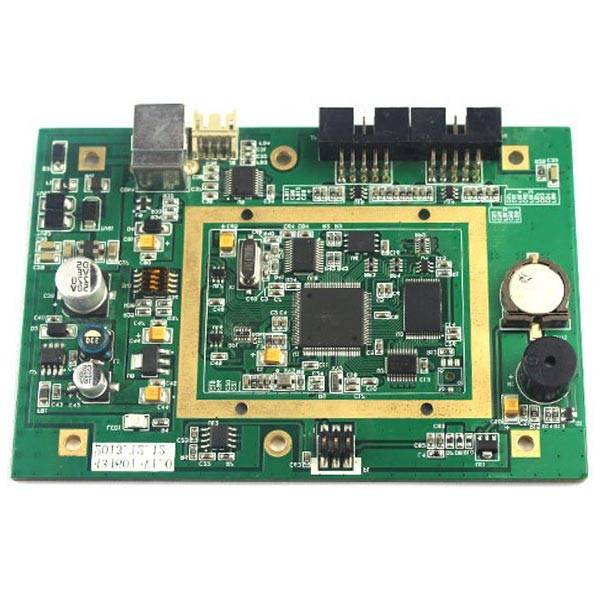

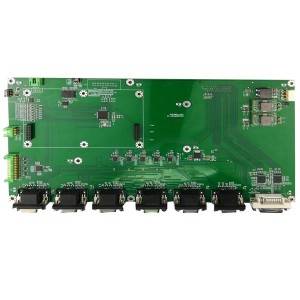

FPGA High-Speed Circuit Board Assembly

Basic Information:

| Metal Coating: Electrolytic Nickel /Hard Gold and Selective Gold | Mode of Production: SMT+ | Layers: 12 Layer PCB |

| Base Material: FR-4+RO4003C | Certification: SGS, ISO, RoHS | MOQ: No MOQ |

| Solder Types: Lead-Free (RoHS Compliant) | One-Stop Services: PCB Manufacturing And Turnkey PCB assembly | Testing: 100% AOI / X-ray / Visual Test |

| Tehnology Support: Free DFM (Design For Manufacturing) Check | Types Of Assemblies: SMT, THD, DIP, Mixed Technology PCBA | Standard: IPC-a-610d |

PCB and PCBA Quick Turn PCB Assembly

Keywords: PCB Assembly, PCB manufacture, PCB Population, PCB Assembly Manufacturers, PCB Assembly Cost, Cheap PCB Assembly, Printed Circuit Board Assembly Companies

PCBFuture is a PCB manufacture and PCB Assembly Company. With more than 20 years of outstanding excellence, world-class talent and innovative breakthroughs, PCBFuture has come a long way to become one of Chinese leading PCB designers and producters today. Our focus on high-quality and economically viable systems combined with unmatched consistency has made us the firm of choice throughout China.

Why choose PCBFuture?

1. Strength guarantee

SMT workshop: we have imported placement machines and multiple optical inspection equipment, which can produce 4 million points per day. Each process is equipped with QC personnel to maintain product quality.

DIP production line: There are have two wave soldering machines. The workers are skilled in welding various plug-in materials.

2. Quality assurance, high cost performance

High-end equipment can paste precision shaped parts, BGA, QFN, 0201 materials. It can also be used as a model for manual installation and placement of bulk materials. Both samples and large and small batches can be produced.

3. Rich experience in SMT and soldering of electronic products, stable delivery

Provide accumulated services for thousands of electronics companies, involving SMT chip processing services for various types of automotive equipment and industrial control motherboards. The products are exported to Europe and the United States Frequently, and the quality can be affirmed by new and old customers.

The materials will be delivered on time within 3-5 days after normal completion, or they can be delivered on the same day.

4. The strong maintenance ability and perfect after-sales service

The maintenance engineer has rich experience and can repair defective products caused by various repair welding, and we can ensure the connection rate of each circuit board.

The customer service will respond at any time within 24 hours and resolve your order as soon as possible.

The PCBA production process:

- SMT patch processing

- DIP plug-in processing

- PCBA testing

- Finished product assembly

The advantages of industrial control board PCBA foundry material of PCBFuture:

- The Low purchase cost. We have professional procurement personnel who are proficient in electronic materials and have long-term cooperation with high-quality and reliable procurement channels. It is basically achieving zero material MOQ costs.

- Reduce labor costs, we are equipped with electronic purchase, electronic engineers, electronic materials and parts IQC, the customers don’t need to configure.

- In order to reduce material costs, we are equipped with a variety of electronic inspection equipment, the customers don’t need to configure.

- Greatly reduce communication costs, customers don’t need to dock multiple raw material suppliers, we will help them complete the service.

- The Clear responsibilities. If there is a quality problem, the customer don’t need to judge whether it is a raw material problem or a manufacturing process problem. We are fully responsible.

PCBFuture is a PCBA OEM manufacturer that can provide customers with professional PCB manufacturing, material purchase, PCBA one-stop rapid production and other high-quality services with customers. If you have any questions or enquire, feel free to contact sales@pcbfuture.com , we will reply to you ASAP.